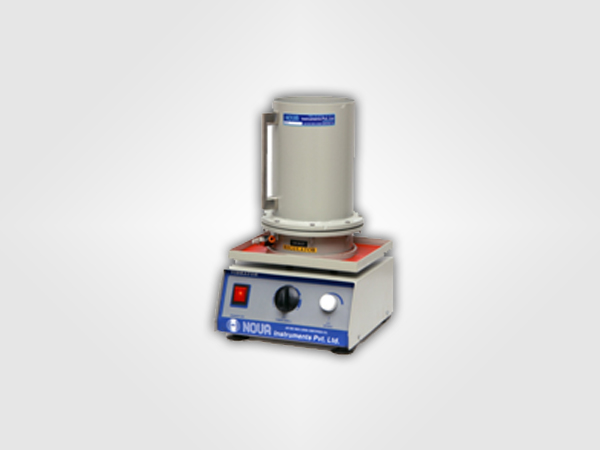

"NOVA" Sample preparation using dipping-coating unit (Single and Double) is designed to keep operator involvement as minimum as possible by automizing process. Speed, duration are Regulated accurately by microprocessor control.

Coating powder kept in fludize bed, predefined heated sample immerse into a coating powder for durations (Auto Timer Mode) as per standards and allowing it to deep. The coated piece can then be dried by force-drying or baking. A microprocessor based system takes care of accurate control throughout the process. Machine is design on four step process can be done in few seconds. The System comes with Sample holding magnetize arm and control system.

[FOR OTHER SIZE PLEASE CONTACTUS]

| MICRO CONTROL BASED | PLC HMI CONTROL BASE | |

| SINGLE DIPPING UNIT | ||

| DOUBLE DIPPING UNIT |

Film formation on dipping is dependent on the material resistivity. Resistivity of the material should remain practically constant for the equally coating at all surface of the sample. Dipping-coating is well suited for high quality coating of relatively all shapes. The process to reduce its resistivity and which make coating material act like fluid is called fluidization. Process is to make it fluidized by applying air through it. Unit is supply with instrument that makes act powder as fluid during coating process.